Raycus 100W MOPA Laser Fiber Marking Machine Color Fiber Laser Engraver

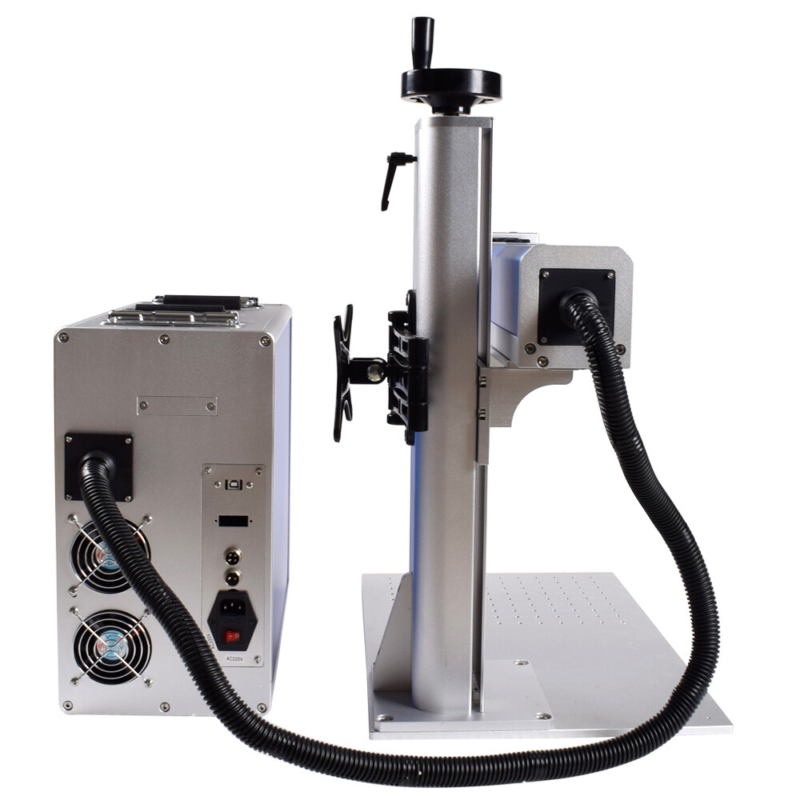

Item No.: ZS-MOPA-P100MX

Color Marking

Built-in Laser Source Brand: Raycus

Laser Model: RFL-P100MX MOPA Fiber Laser

Average Output Power: 100W

Laser Wavelength: 1064nm

Laser Class: Class2

Contact us for price list please.

INQUIRY

Description

MOPA ,UV And Optical Fiber Lasers Differences

2D /2.5D/3D Differences

Raycus 100W MOPA Laser Fiber Marking Machine Color Fiber Laser Engraver

| Machine Type |

MOPA Fiber Laser Engraver Color Marking Machine |

| Built-in Laser Source Brand |

Raycus RFL-P100MX MOPA Fiber Laser |

| Average Output Power |

100W |

| Laser Wavelength |

1064nm |

| Laser frequency |

20-1000 kHz |

| Output power instability |

<3% |

| Output Beam Diameter |

6.5±1mm |

| Light Beam Quality |

M²:<1.6 |

| Polarization state |

random |

| Pulse Width Range(ns) |

10-350(Customizable) |

| Max.Single Pulse Energy(mJ) |

1 |

| Life Span of fiber laser module |

100,000 hours |

| Marking Line Speed |

≤8000mm/s |

| Minimum Line Width |

0.012mm |

| Minimum Character |

0.15mm/depends on the material |

| Marking Depth |

≤1.2mm/depends on the material |

| Repeating Precision |

±0.001mm |

| Focus Spot Diameter |

0.01mm |

| Output Power of Laser |

10%~100% continuously to be adjusted |

| Temperature/Humidity |

15℃~40℃/10%~95% |

| Total Power Consumption |

≤400W |

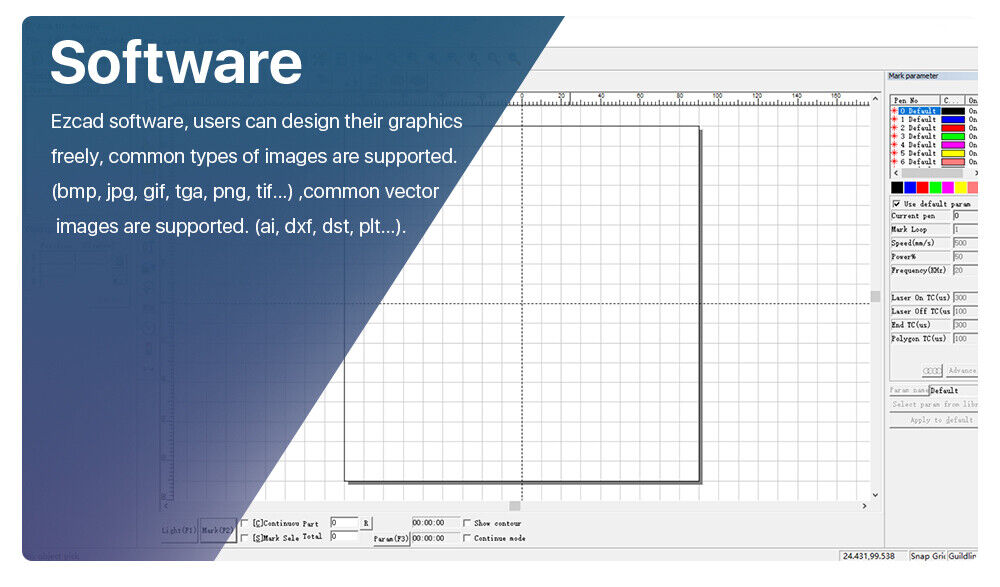

| Operating System |

Windows System |

| Cooling System |

Air-cooled |

| Communication |

Standard USB2.0 |

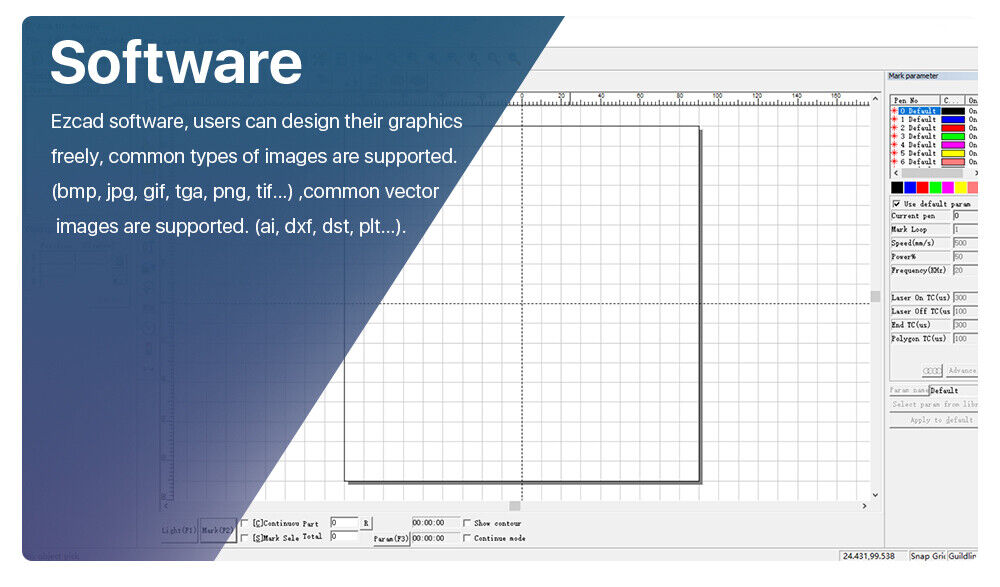

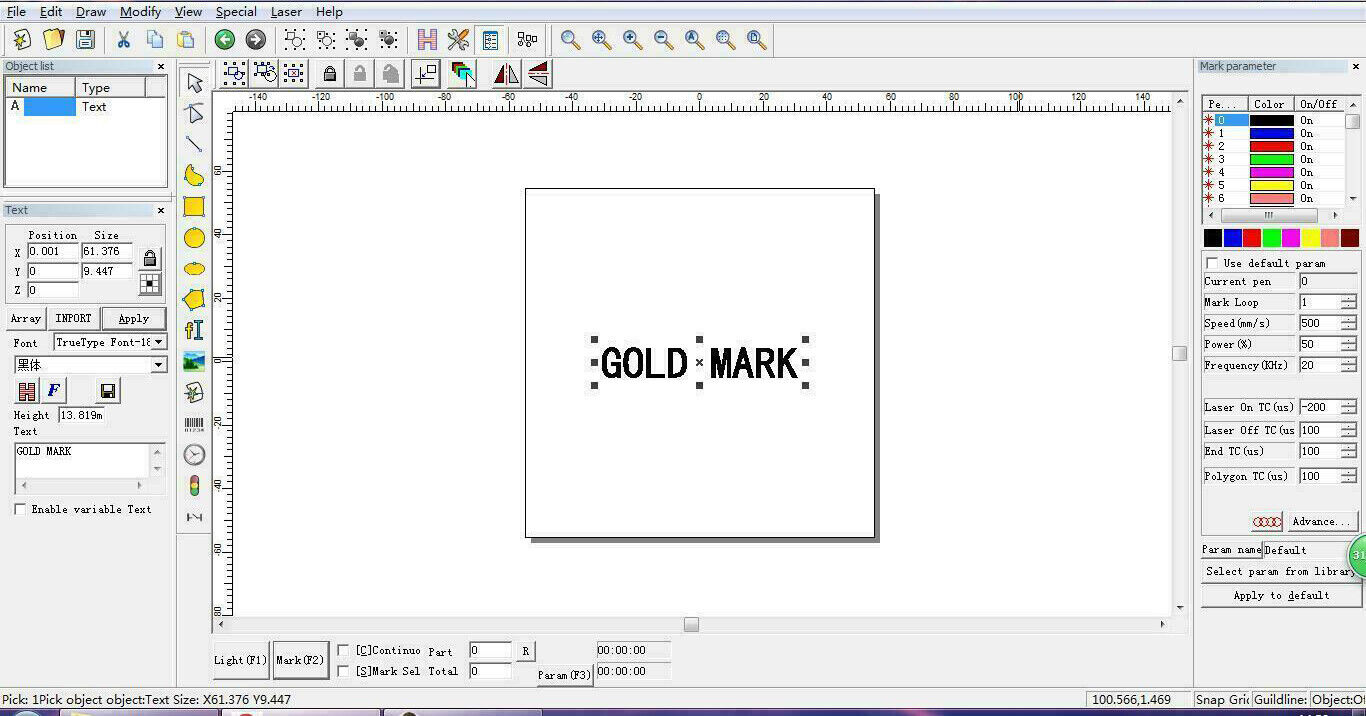

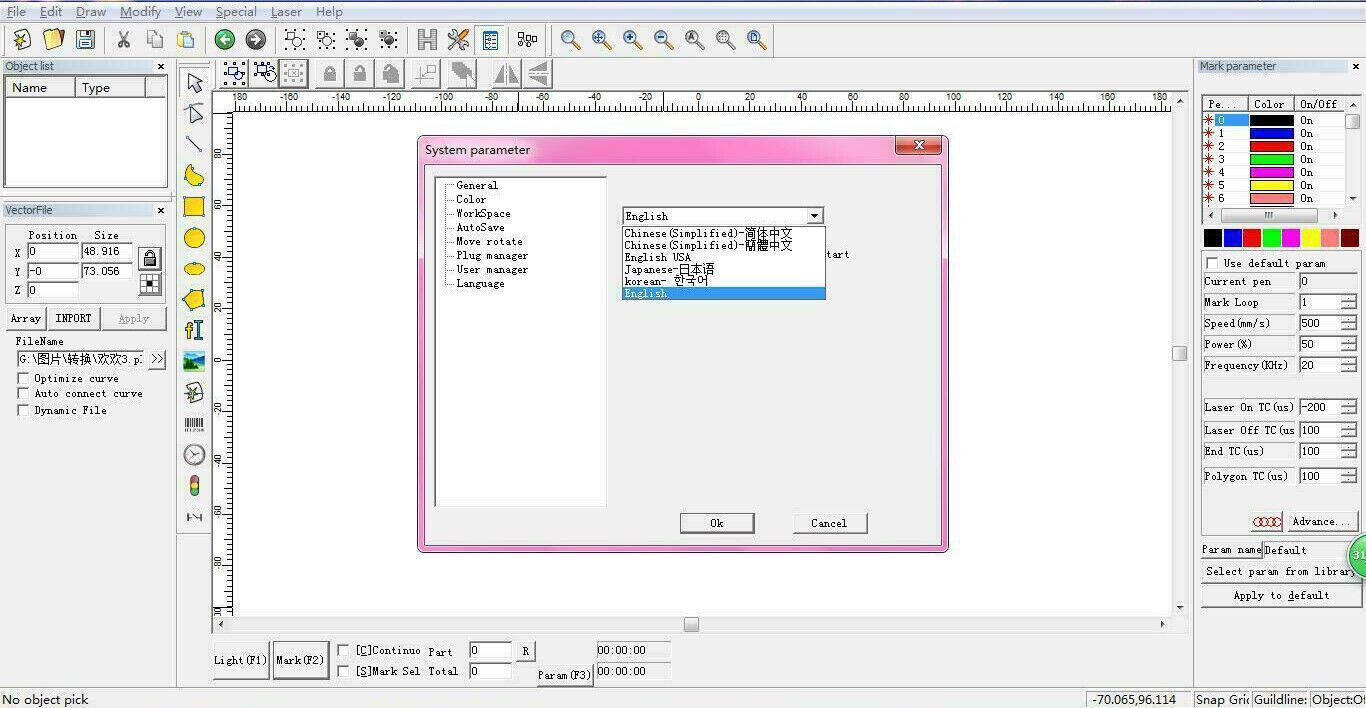

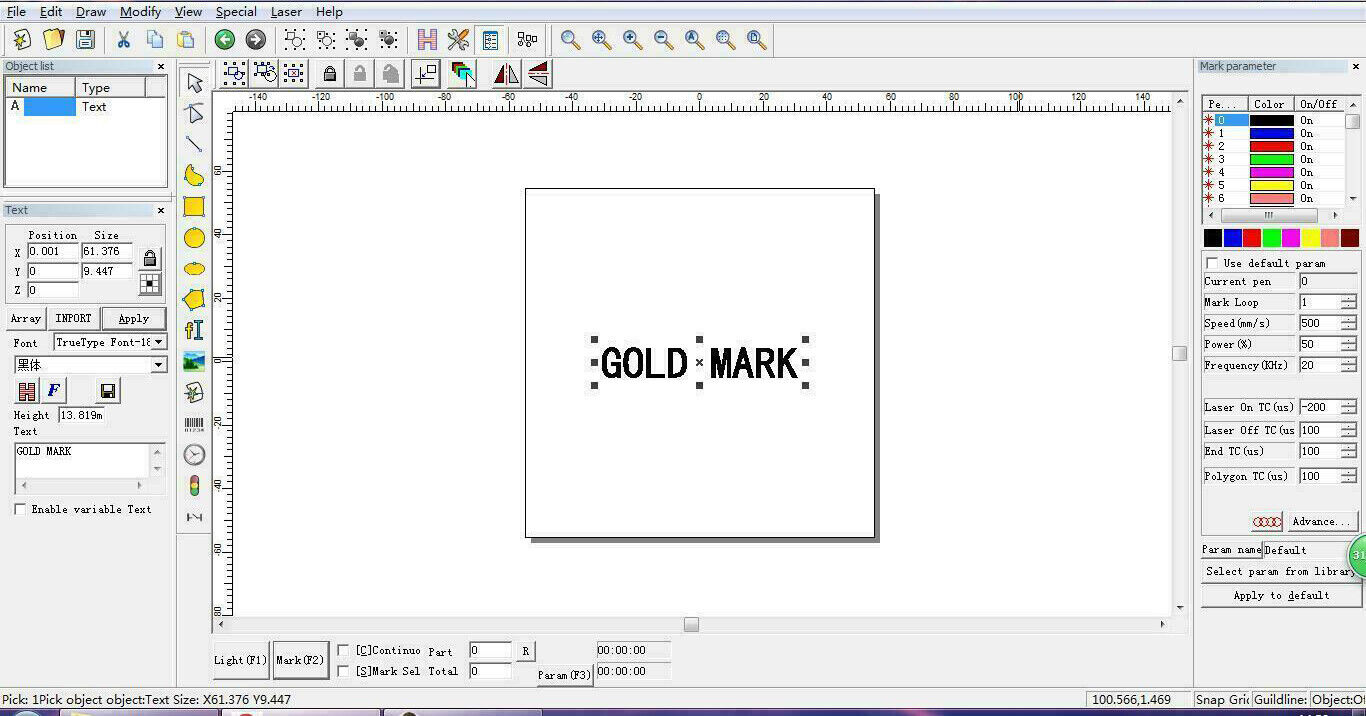

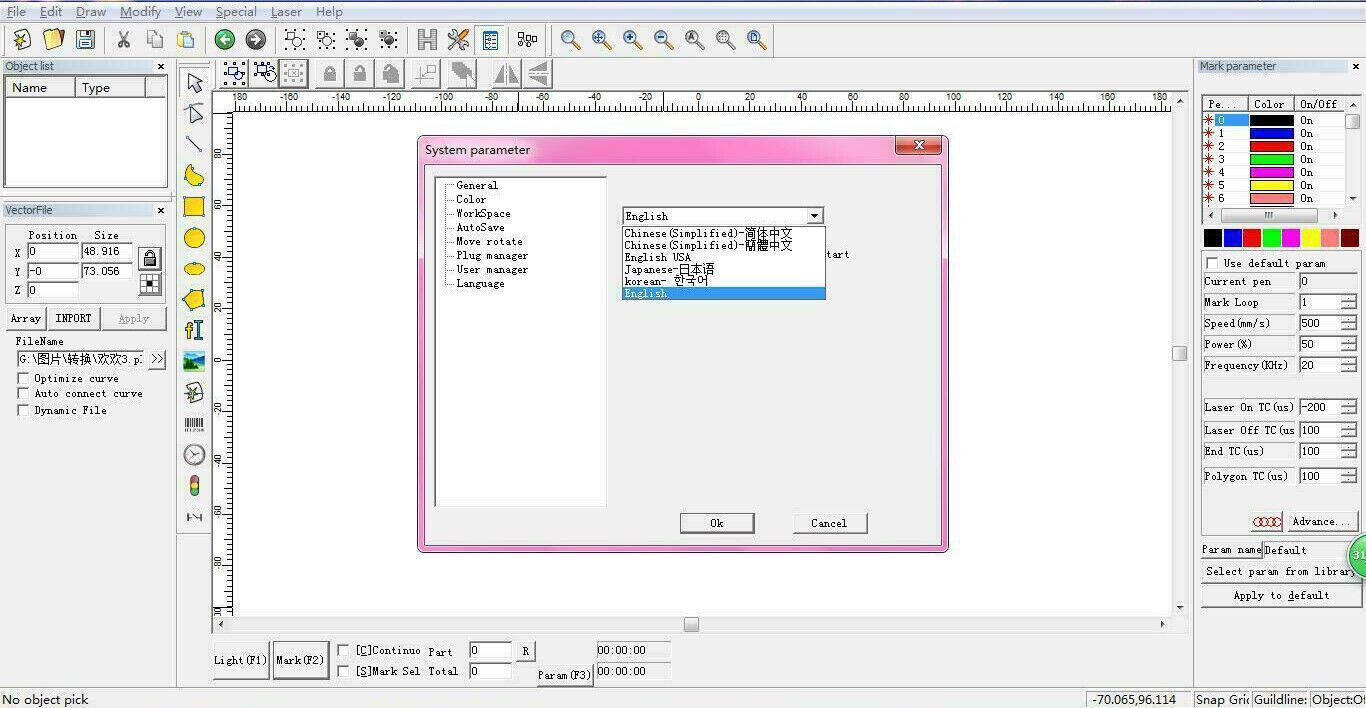

| Control Software |

Ezcad (Easy to use) |

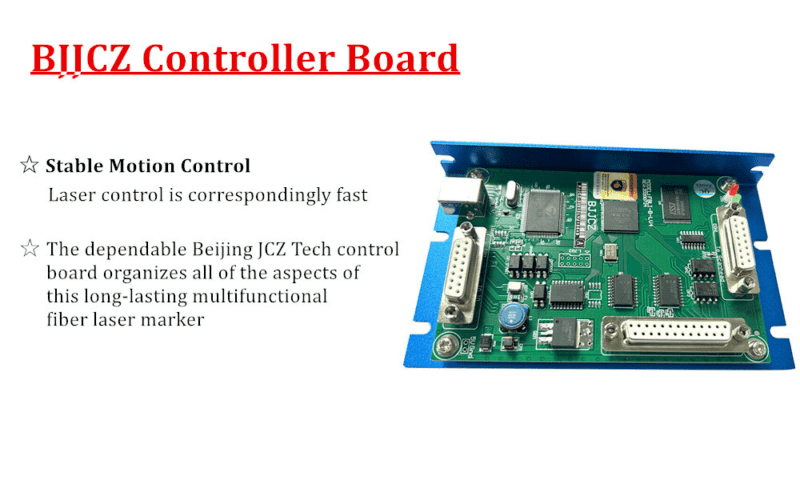

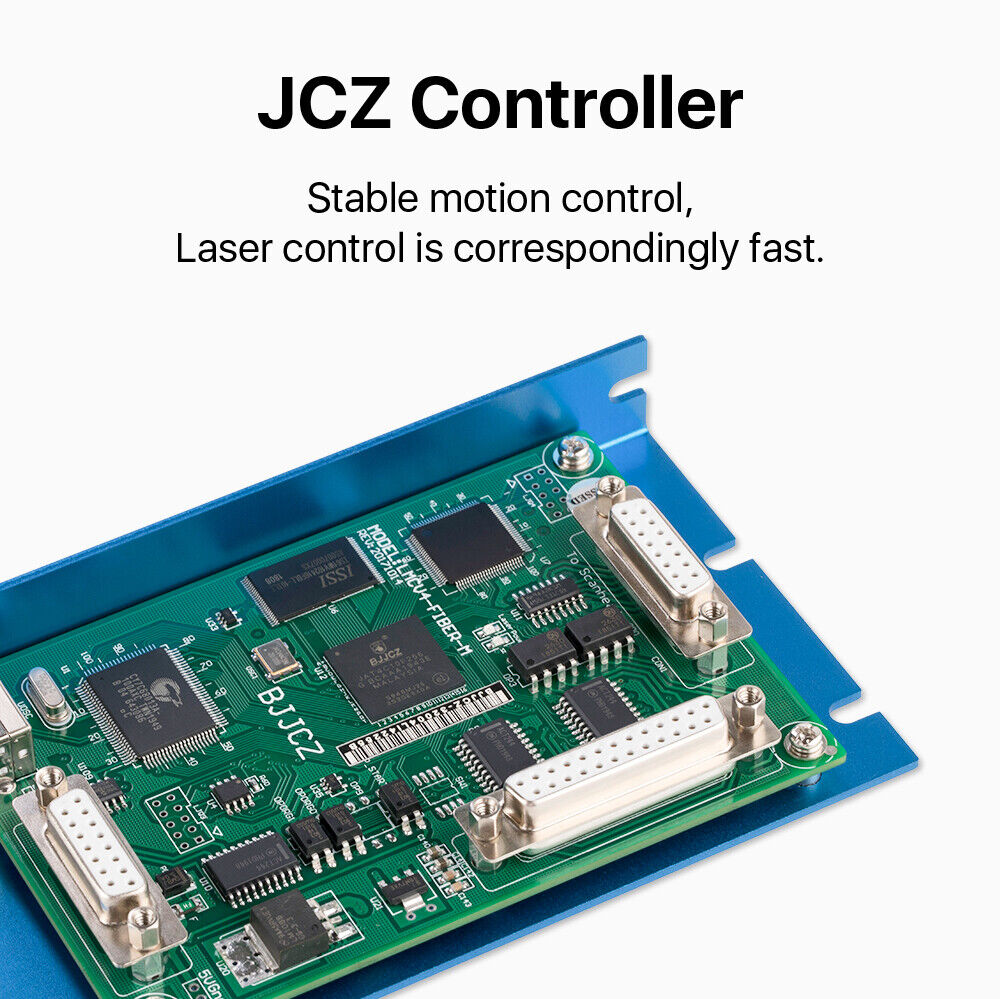

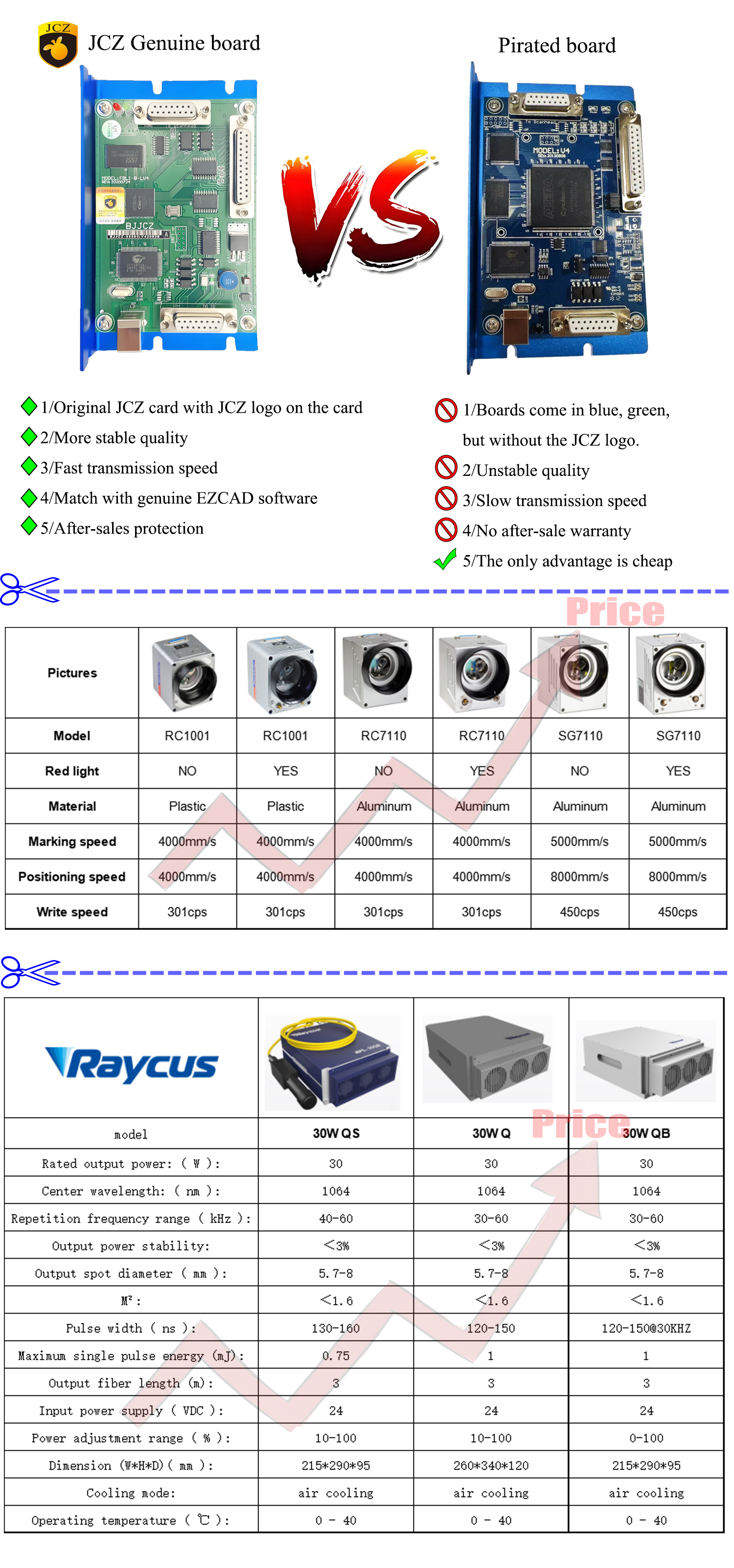

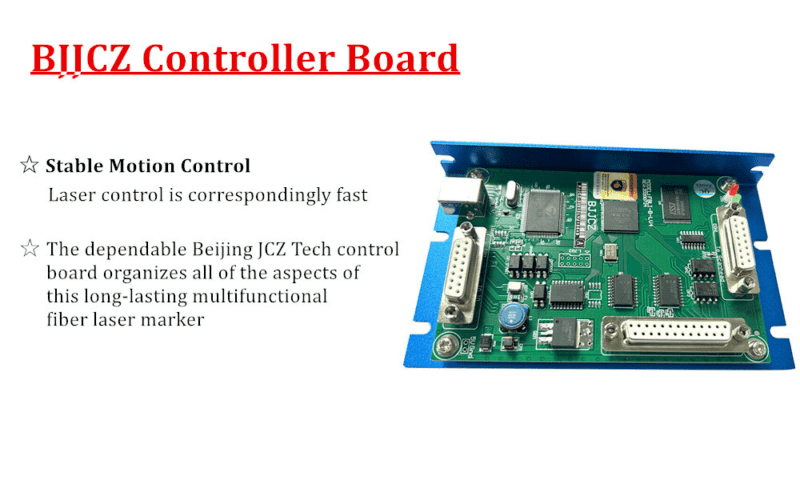

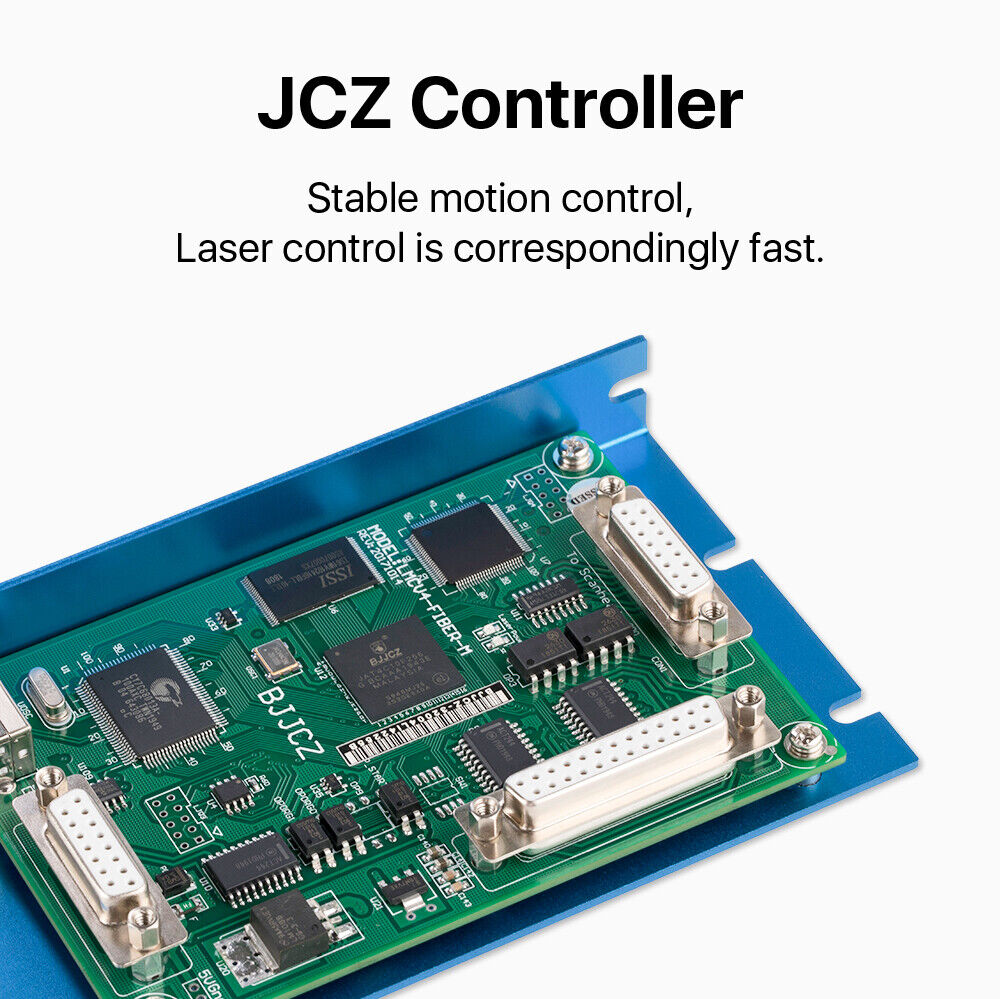

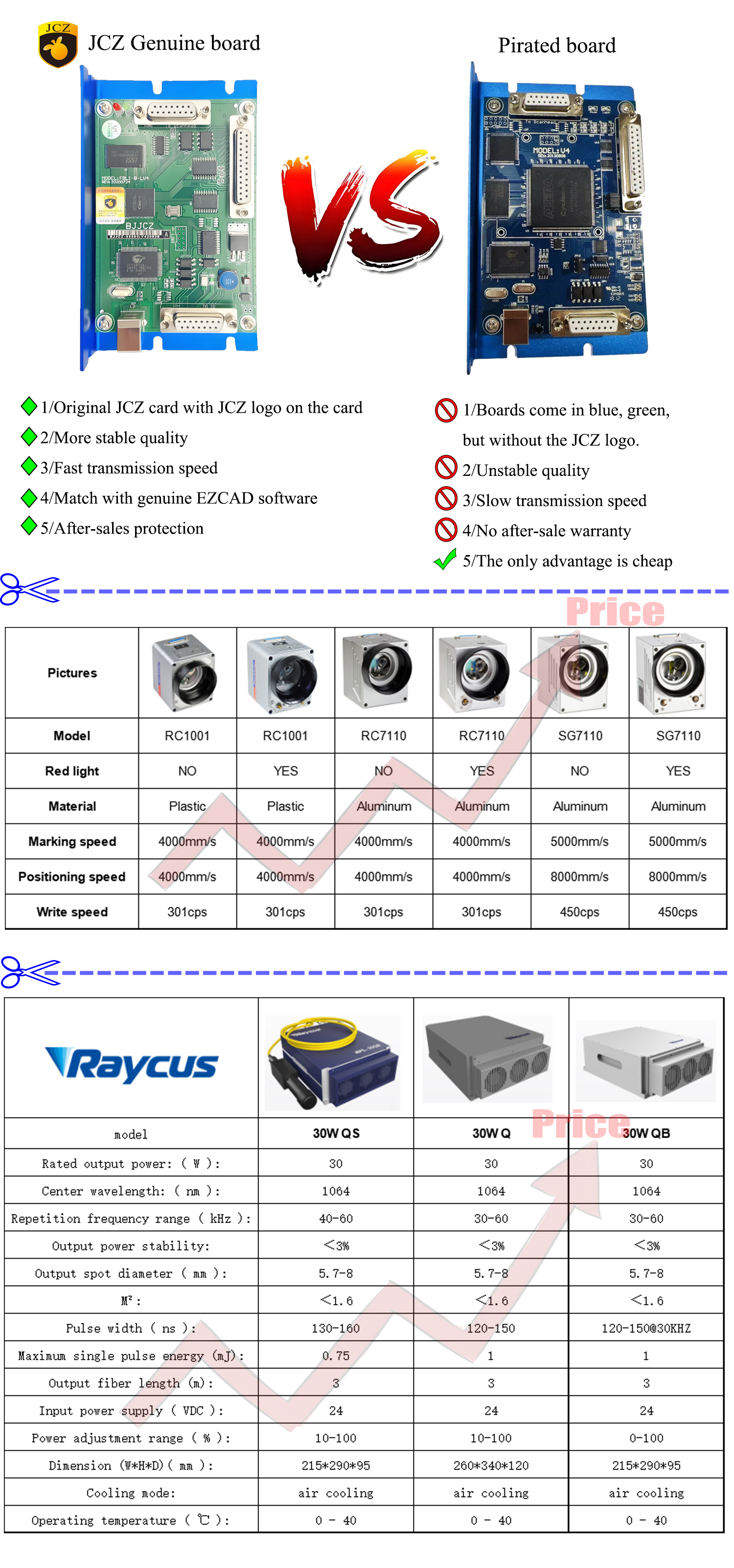

| Control Board |

BJJCZ (Original Version) |

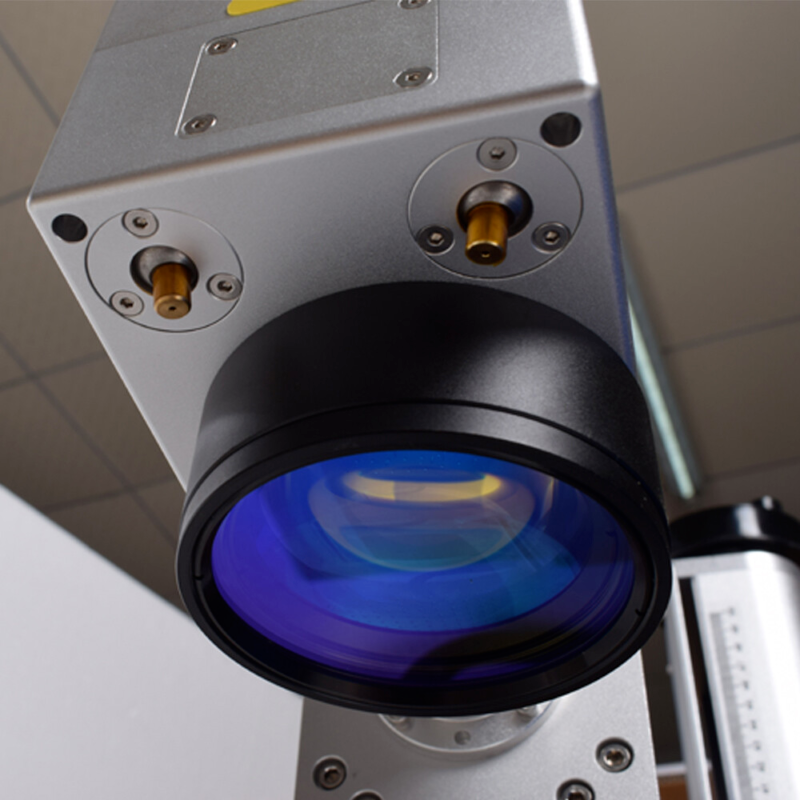

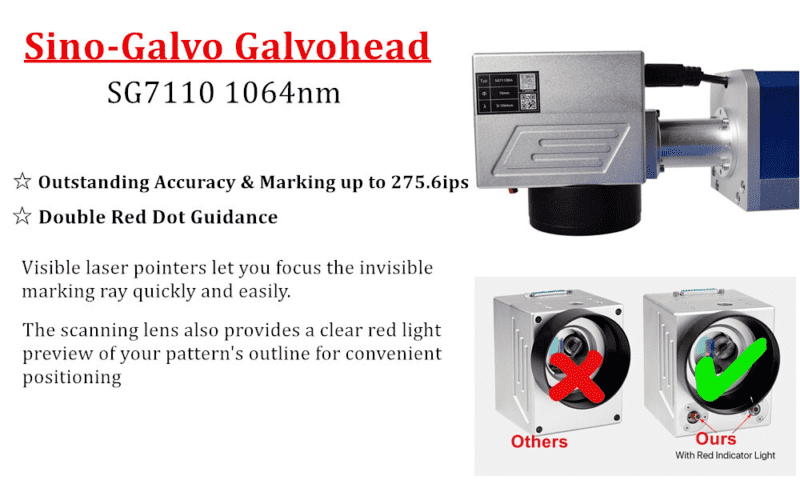

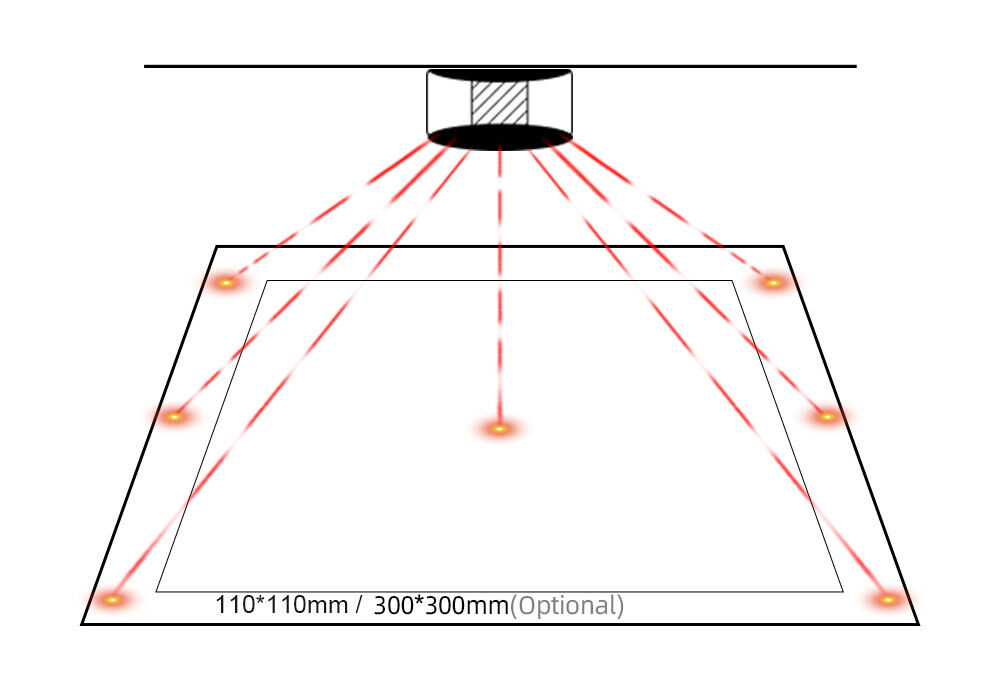

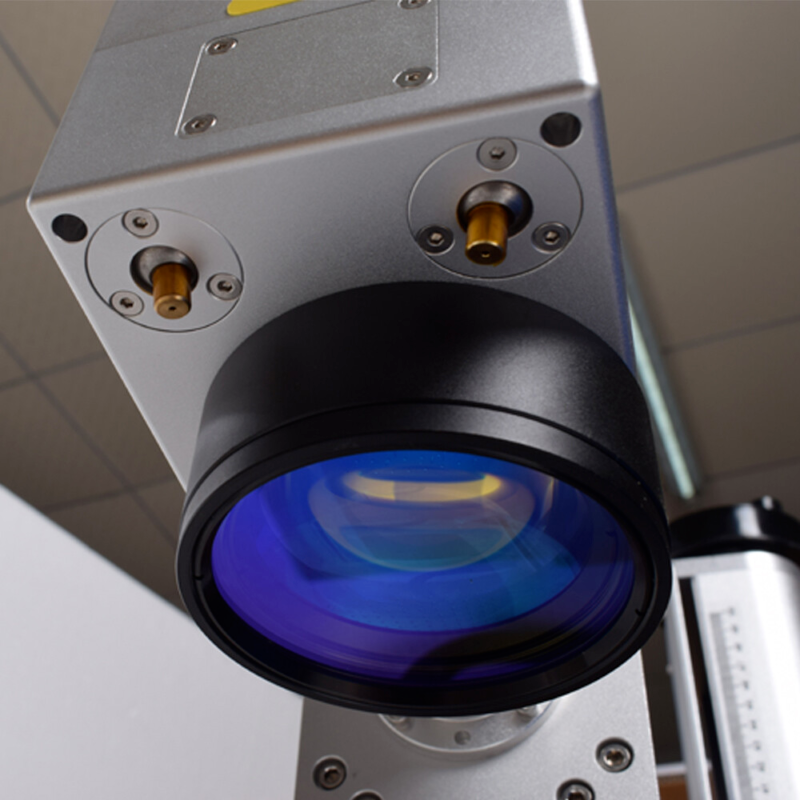

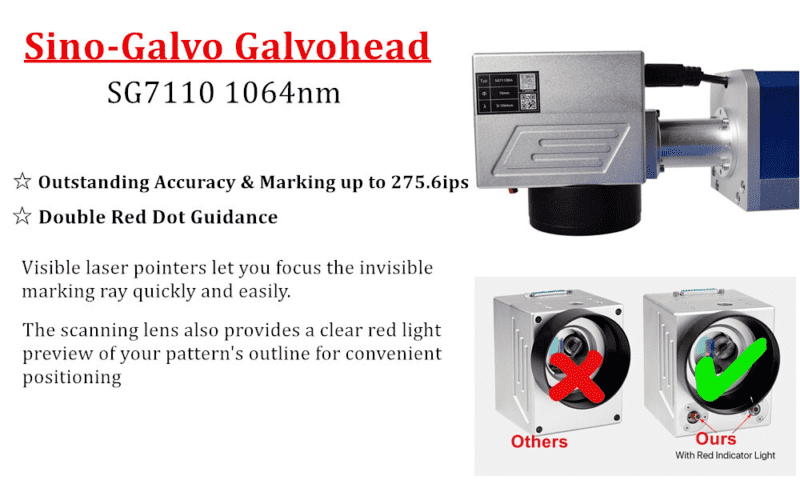

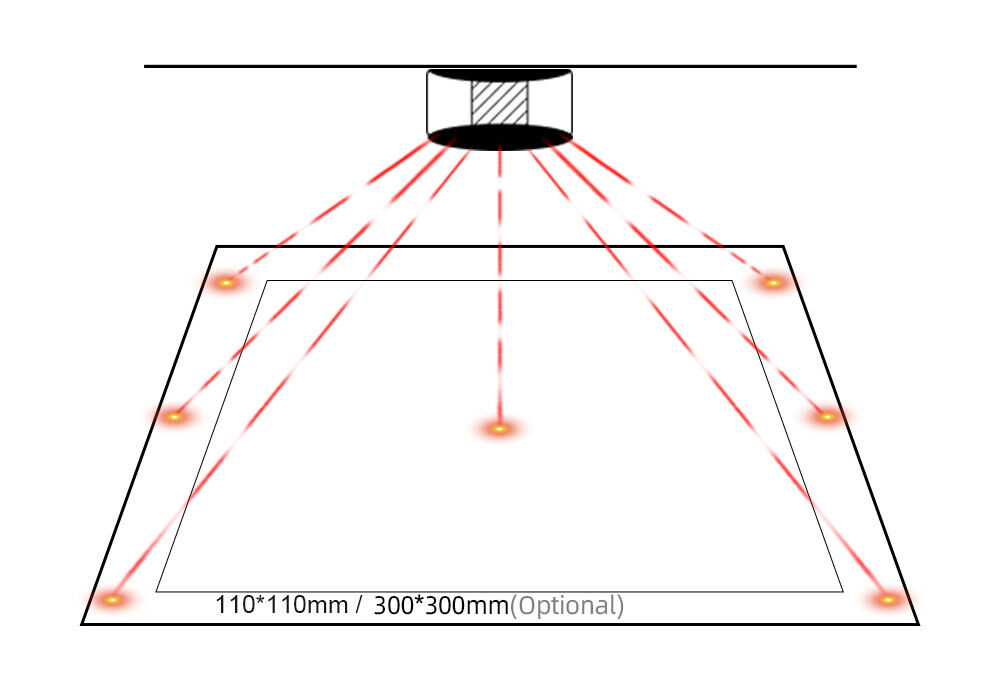

| Galvanometer(Optional ) |

RC 1001 K9 / SINO SG7110 K9 |

| Marking Area(Optional ) |

110mm*110mm (4.3"X4.3") |

| F-theta Lenses Size |

175mm*175mm (6.8"X6.8") |

| |

200mm*200mm (7.8"X7.8") |

| |

300mm*300mm (11.8"X11.8") |

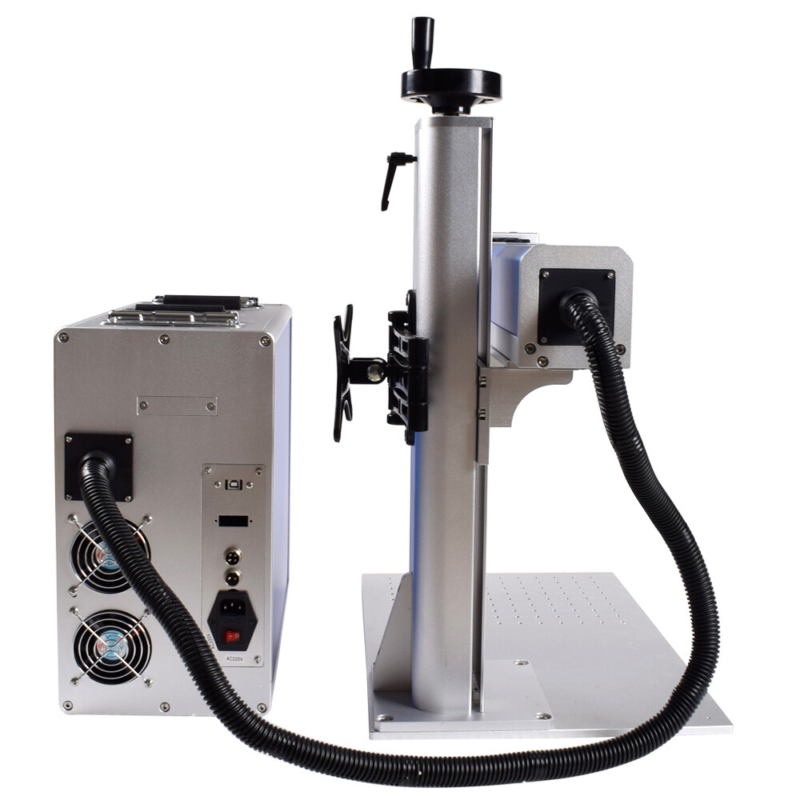

| Package Size |

82*67*52cm |

| Gross Weight |

59KG |

Operation Software Languages: Spanish, French, Italian, Japanese, Korean, Portuguese, Russian, Thai, Turkish

Operation Software Languages: Spanish, French, Italian, Japanese, Korean, Portuguese, Russian, Thai, Turkish

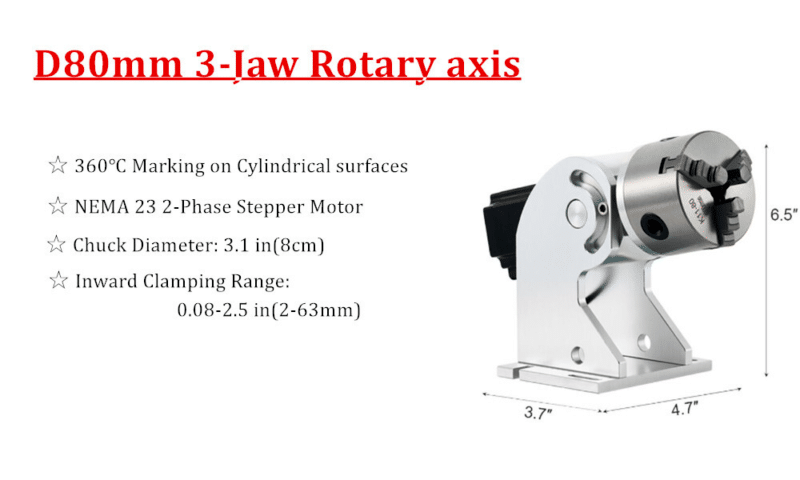

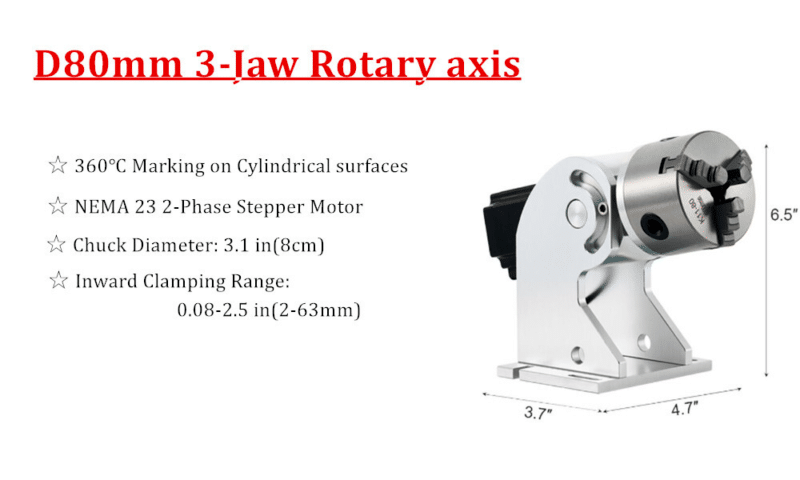

80D Rotary Axis (Optional )

80D Rotary Axis (Optional )

Applications

Applications

What’s the difference between MOPA ,UV land Optical Fiber Lasers?

Those new to laser marking, or those only familiar with one type, may be unaware of the various forms the process takes when it comes to both the laser and its marking capabilities. In this post, we’ll take a look at MOPA fiber lasers vs. UV lasers vs. Optical Fiber lasers, examining the differences and similarities between the options.

When companies and hobbyists turn to laser marking for their engraving needs, they usually have specific applications in mind. Whether they need a system to engrave a company logo, add serial numbers and other traceability codes, or personalize a product for a customer, laser marking is the answer, supplying diverse functionalities and providing repeatable solutions.

UV marking machines use 355nm UV lasers, while fiber optic marking machines use 1064nm wavelength lasers

The short wavelength of the UV laser allows it to focus more precisely, producing fine circuit characteristics while maintaining excellent positioning accuracy. UV fiber laser marking machines can mark both metallic and non-metallic materials, especially hard and brittle ones. Flexible PCB board marking: scribing and cutting, LCD liquid crystal glass two-dimensional code marking, glass appliance surface perforation, metal surface plating marking, plastic buttons, electronic components, communication equipment, construction materials, etc..

High-end market products: cosmetics, pharmaceuticals, video and other polymer materials, packaging bottles surface marking, adapted to ultra-fine processing, the effect is fine, marking cleaning firm, better than inkjet code and no pollution.

Plastic products: including silicone products, glass products, jade, jadeite, ceramics, acrylic products, etc. It can be used for engraving LOGO trademarks, text, patterns, two-dimensional code, serial number, anti-counterfeiting code, etc. on the products.

Surface marking of metal or non-metal: applicable to electronic mobile phone parts, LCD screen engraving QR code and trademark, ceramics, sapphire chip, FPC flexible circuit board micro-hole drilling, cutting, biomedical glass scribing, etc.

The ultraviolet marking machine has a very small focus spot. Small, heat-affected zone is small, suitable for ultra-fine marking, engraving, especially for food and pharmaceutical packaging materials marking, playing microporous, glass materials, high-speed division and silicon wafer complex graphic cutting and other application areas. A fiber marking machine can mark metal surfaces, but not high-precision materials. It's cheaper to buy and easier to maintain than a UV laser marking machine. When choosing, consider your actual demand and the marking of special materials. Also consider the price, maintenance difficulty and other factors to ensure the long-term stable operation of the equipment.

Applications For 1064nm fiber optic marking machines As follows,

Applications For 355nm UV fiber optic marking machines As follows,

MOPA Fiber Laser Marking Machine (Colorful Engraving Marking)

Mopa fiber laser marking machine provides the best solution for color marking.

What is color laser marking?

Color laser marking is a process of using a laser to add color marks to the surface of a material. Different from ordinary black and white marking, color marking provides customers with more laser design solutions.

What is Mopa laser?

MOPA is the abbreviation of “Main Oscillator and Power Amplifier”. In industrial manufacturing, MOPA laser refers to nanosecond pulse fiber laser based on electric modulation seed source and multi-stage power amplifier. It is mainly used in laser marking, cutting, welding, drilling and engraving.

Fiber lasers often use a wavelength of 1060 nm, which is good for absorbing into many materials. This wavelength is not suited for fragile materials like wood and glass, but it is ideal for steel, stainless steel, titanium, aluminium, brass and copper, ABS plastic, polyethylene, gold and nickel plating, black oxide, painted materials, anodised aluminium, carbide and PCD.

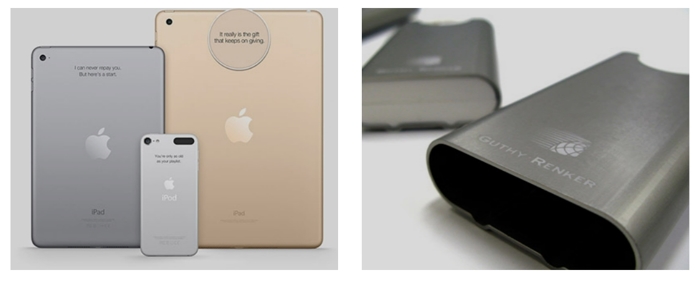

Typical applications for color laser marking machine

Stainless steel

Anodized aluminum

Plastic

All fiber laser marking machines are 2D marking machines in factory's standard production.

We support to upgrading your machines to 2.5D or 3D fiber laser marking machines.

Please feel free to contact us contact us if there is any questions.